Open Access

Open Access

ARTICLE

Physical and Mechanical Properties of Gmelina Wood (Gmelina arborea Roxb.) Modified with Furfuryl Alcohol-Tannin

1 Faculty of Forestry and Environment, Department of Forest Products, IPB University, Bogor, 16680, Indonesia

2 Research Center for Biomass and Bioproducts, National Research and Innovation Agency (BRIN), Cibinong, 16915, Indonesia

3 The Papua New Guinea University of Technology, Independence Drive, East Taraka, Lae 411, Papua New Guinea

4 College of Landscape and Horticulture, Yunnan Agricultural University, Kunming, 650201, China

5 INRAE, LERMAB, Université de Lorraine, Nancy, 54000, France

* Corresponding Authors: Mahdi Mubarok. Email: ; Saefudin. Email:

Journal of Renewable Materials 2025, 13(4), 731-752. https://doi.org/10.32604/jrm.2024.057476

Received 19 August 2024; Accepted 28 November 2024; Issue published 21 April 2025

Abstract

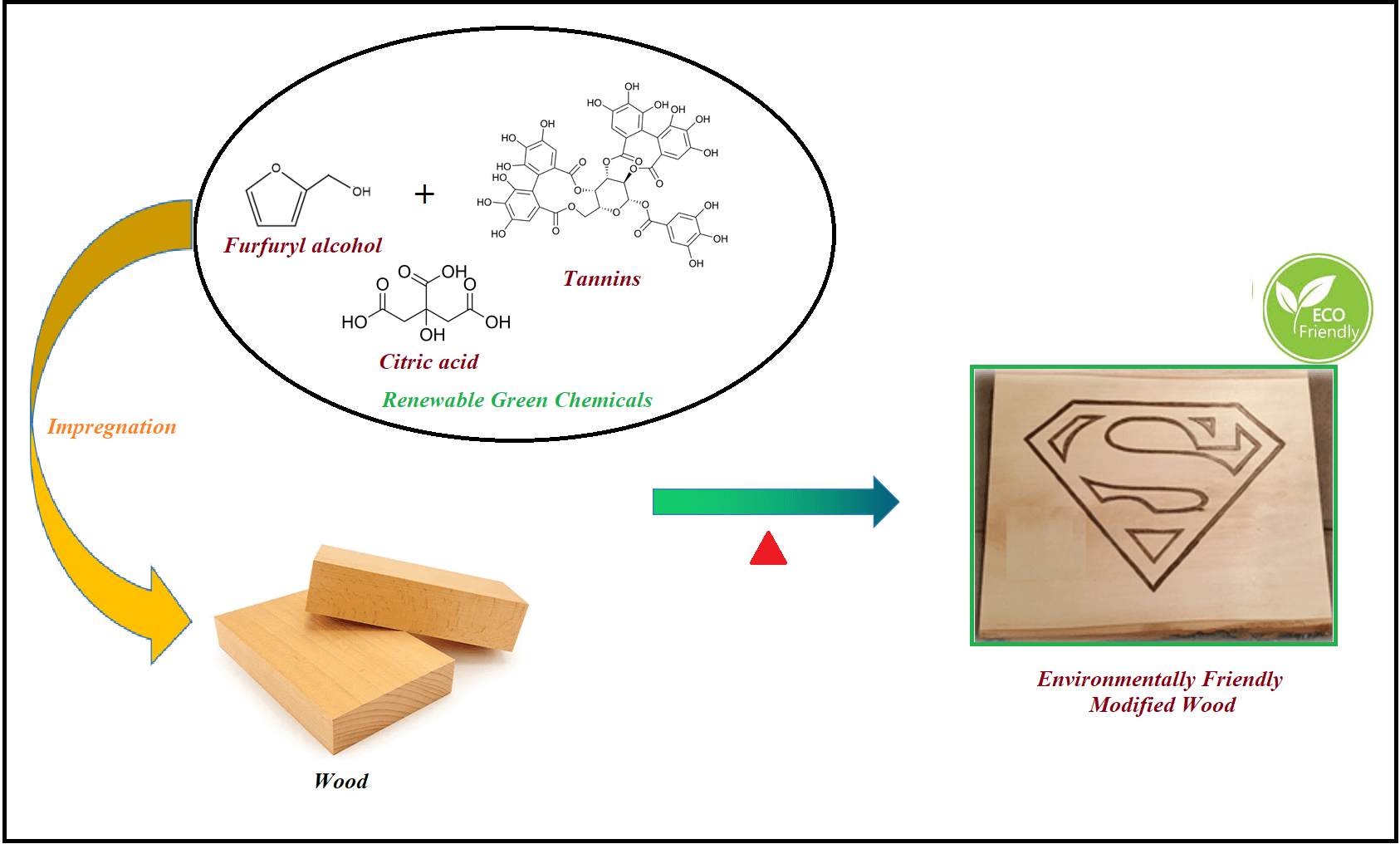

Furfurylation, a renowned chemical modification technique, uses furfuryl alcohol to enhance the properties of wood. This technology can be further refined by incorporating renewable tannins, which promote cross-linking with furfuryl alcohol. This study investigates the effects of furfurylation and tannin-modified furfurylation on the physical and mechanical properties of tropical Gmelina wood (Gmelina arborea Roxb.). Experiments involved impregnating Gmelina wood with aqueous solutions of furfuryl alcohol (FA) at 40% and 70% concentrations, as well as FA-tannin combinations (FA 40%-TA and FA 70%-TA), followed by polymerization at 103°C. The results demonstrated that both FA and FA-tannin treatments significantly improved the wood’s physical and mechanical properties. Notably, FA-tannin treatments achieved anti-swelling efficiency comparable to FA alone. However, the addition of tannins (FA 70%-TA) enhanced leaching resistance by up to 47%, contributing to a more environmentally sustainable modification process. Mechanically, the inclusion of tannins in FA 70%-TA slightly increased the modulus of elasticity (14%~8732 kg/cm2) and the modulus of rupture (9%~40.9 kg/cm2). Furthermore, the tannin addition imparted a darker color to the modified wood, enhancing its aesthetic appeal. This study highlights the potential of tannin-modified furfurylation to advance wood modification technology, combining improved performance with environmental benefits.Graphic Abstract

Keywords

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools